Why do you need to have a Test Database?

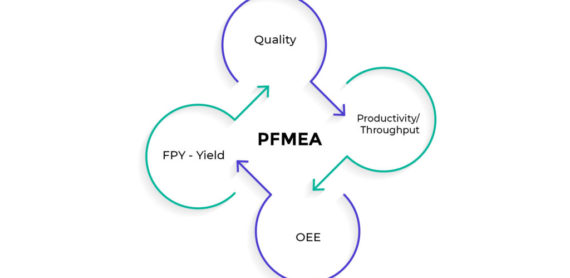

ATE produce lot of critical test data during testing which helps to improve the manufacturing process, quality and the reliability of the product. Manufacturing, Test, Process, Quality and Product engineering team depend on the test data to drive the actions to improve the product quality regularly.