TEST WITH CONFIDENCE.

World class leader in Automated Test Equipment’s, Manufacturing Data Analytics- Industry 4.0 & Control Engineering Solutions

Automated Test Equipments

Board Level testing, End Of Line Testing, Environmental Testing, Agency testing, Bed of nails Fixtures, Process Model framework & many more custom test solutions.

Connected Factory- Industry 4.0 Solutions

With Real-time data monitoring, Dashboards and smart triggers, Connect the unconnected machines, run the factory with Intelligent connectivity and Production Trend Data Analytics.

Control Engineering, Control Automations and Vision Automations

We custom design and monitor the quality, safety, and efficiency of your lab and factory control systems and Vision automation for part inspection and calibrations.

TestStand / CVI / LabVIEW Consultant

Testamatic can deploy highly skilled Certified TestStand/CVI/ LabVIEW engineers on a short/Long term contract basis to help you meet your deadlines at a fraction of the cost.

Testamatic Launched India's Most Affordable Industrial PC

The Testamatic Systems Industrial PC is a truly rugged and reliable workhorse. Powered by Adlink, it has the capability to run 24/7 while performing most high-reliability computer tasks including Advanced Data Acquisition and Control, Industrial IOT Applications, Test & Measurement, Mining Equipment Control, Weather Station Data Collection, Process Controllers, Power Management Systems and more. Its 12″ wide standard ATX Motherboard provides plenty of expansion capability with room for many more cards beyond what comes pre-installed. With 8GB of installed DDR4 high-speed memory you can be assured your applications will operate well. Windows 64 bit Professional software comes loaded. This rugged industrial computer is housed in a 4U 19 rackmount chassis and capable of running wide range of I/O modules to meet your requirement.

Industries We Cover

Test with confidence as we have over 9 years of experience in test automation pertaining to all these domains.

Test the right signal with high accuracy, resolution and uncover the manufacturing trend with our data analytics

With over 150 projects and custom solutions

SATISFIED CLIENTS

CERTIFICATION & ALLIANCE

Why Testamatic Systems?

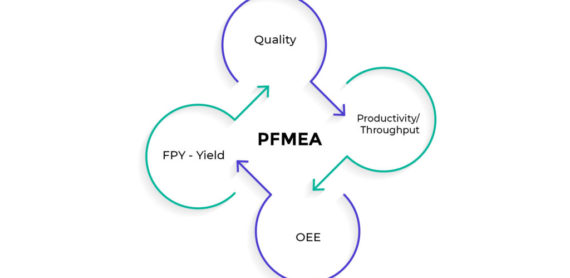

With the wide working experience with Test Engineering and advanced manufacturing industries with deep knowledge of the electronic manufacturing process and its KPI’s. We transform our experience into our design and development of Automated Test Equipment and Manufacturing data analytics- Industry 4.0 solutions. We also offer Automated Test Equipment solutions NPI/NPD/Product Validation. We strive for our customers success with the right solution for the right application to meet the critical parameters of a manufacturing industry.

Working Process

FEATURED CASE STUDIES

LATEST NEWS

issues facing managers today.

Importance of PFMEA while designing an ATE Systems

7 Reasons to design the ATE to be industry 4.0 compliant

REQUEST A CALL BACK

Thank you for your interest in Testamatic Systems. Please fill out the

form below to ask a question. We will get back to you

with 1-2 business days.